Pigging Application in Pharmaceutical Industry: Ensuring Safety and Efficiency

In the pharmaceutical industry, product safety, cleanliness, and regulatory compliance are critical aspects that govern every stage of production. Pharmaceutical manufacturers work with various raw materials, intermediates, and finished products, all of which require stringent care to avoid cross-contamination and ensure the highest quality standards. One of the key technologies that has become an industry standard to address these concerns is the pigging application in pharmaceutical industry. Pigging systems are used to clean, separate, and inspect pipelines in a way that ensures the safe and efficient flow of pharmaceutical products through manufacturing processes.

This article delves into how pigging application in pharmaceutical industry enhances production safety, product quality, and operational efficiency, along with the advantages it brings to pharmaceutical manufacturers.

What is Pigging in the Pharmaceutical Industry?

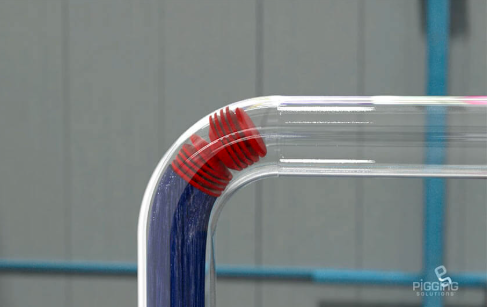

Pigging refers to the use of a mechanical device called a “pig,” which is inserted into pipelines to perform various tasks, such as cleaning, separating different products, and inspecting the condition of pipes. The term “pig” stands for Pipeline Inspection Gauge, and these devices are commonly used in the pharmaceutical industry to ensure that production lines are kept free from contaminants and residues that could otherwise compromise the quality of pharmaceutical products.

In the pharmaceutical industry, the primary function of pigging systems is to ensure the pipeline remains clean and contamination-free between different production batches. By using a pig to clean the pipeline and remove any leftover materials from previous products, manufacturers are able to maintain the purity of their new products. This is especially important in the production of oral medications, injectables, and other pharmaceutical products where even the smallest trace of contamination can be harmful to consumers.

Preventing Cross-Contamination

One of the most important reasons for implementing pigging application in pharmaceutical industry is the need to prevent cross-contamination between different batches of products. In pharmaceutical manufacturing, products are often made using very specific ingredients, each of which must remain separate to maintain the integrity of the drug. If even a trace of one product mixes with another, it can result in serious issues such as reduced efficacy, potential side effects, or even harmful reactions.

Pigging systems address this challenge by cleaning the pipeline between product batches. For example, if a pharmaceutical plant is manufacturing a batch of painkillers followed by a batch of antibiotics, the pig will remove any remaining trace of the painkiller from the pipeline before the antibiotics are introduced. This process prevents contamination and ensures that each product batch remains pure and safe for consumer use.

Enhancing Regulatory Compliance

Pharmaceutical manufacturing is subject to strict regulations, including Good Manufacturing Practices (GMP), which are guidelines set by regulatory agencies such as the FDA (Food and Drug Administration) to ensure products are made consistently and controlled to the highest quality standards. Compliance with GMP requires pharmaceutical manufacturers to maintain clean facilities and pipelines, preventing contamination and ensuring product safety.

The pigging application in pharmaceutical industry plays a vital role in ensuring compliance with these regulations. With the ability to thoroughly clean pipelines between production runs, manufacturers can prove that they are meeting the stringent hygiene requirements laid out by regulatory authorities. In addition, many pigging systems come equipped with monitoring features that allow manufacturers to track cleaning processes, creating a documented audit trail that can be used for inspection purposes.

By maintaining clean pipelines and ensuring compliance with GMP guidelines, pigging systems not only improve the safety of pharmaceutical products but also help manufacturers avoid costly regulatory fines or sanctions that can arise from non-compliance.

Improving Efficiency and Reducing Downtime

In the pharmaceutical industry, reducing downtime and improving production efficiency is essential for maximizing profitability and meeting demand. Traditional pipeline cleaning methods often require time-consuming procedures such as disassembling parts of the pipeline, manually scrubbing the interior, and waiting for components to dry. This process can take hours or even days, delaying production and causing substantial inefficiencies.

By utilizing pigging systems, pharmaceutical manufacturers can streamline the cleaning process, reducing downtime significantly. Pigging systems are automated and able to perform cleaning cycles quickly and efficiently. This allows manufacturers to quickly switch between batches and resume production without unnecessary delays. The faster turnaround times afforded by pigging systems help pharmaceutical companies maximize output, meet tight deadlines, and avoid bottlenecks in production.

Read also: How Businesses Use AI to Create Images From Text for Ads

Ensuring Product Integrity and Safety

The integrity of pharmaceutical products is paramount. A product’s chemical composition, sterility, and overall quality can be compromised if pipelines are not properly cleaned or if contamination occurs. Even the smallest residue left from a previous batch can have a significant effect on the new product, potentially leading to defects, reduced efficacy, or adverse reactions when consumed by patients.

By using pigging systems to thoroughly clean pipelines, pharmaceutical manufacturers can ensure that every batch produced meets the highest quality standards. The removal of residues and contaminants ensures that the new product is pure and safe, minimizing the risk of contamination and maintaining the integrity of the pharmaceutical product. This helps companies deliver safe, effective medicines to consumers while also safeguarding their brand reputation.

Traceability and Documentation

In the pharmaceutical industry, traceability and documentation are critical aspects of the production process. Manufacturers are required to keep detailed records of every step of the manufacturing process, including cleaning and maintenance procedures. Pigging systems often come with sensors and monitoring capabilities that track cleaning cycles, providing real-time data on the cleaning process. This data can be stored and used for compliance documentation, ensuring that all necessary procedures have been followed.

By maintaining this level of traceability, manufacturers can demonstrate their commitment to product safety and regulatory compliance. In the event of a regulatory audit or inspection, this documentation can be provided to verify that the cleaning and maintenance processes were carried out properly.

Conclusion

The pigging application in pharmaceutical industry is a crucial tool that enhances safety, efficiency, and compliance in the manufacturing of pharmaceutical products. By preventing cross-contamination, improving operational efficiency, reducing waste, and maintaining product integrity, pigging systems play a vital role in ensuring that pharmaceutical products are safe and effective for consumers. As the pharmaceutical industry continues to evolve, the role of pigging systems will remain essential in supporting manufacturing processes that meet stringent quality standards and regulatory requirements. By investing in pigging technology, pharmaceutical companies can improve their production capabilities, reduce costs, and ensure the delivery of high-quality, safe medications to patients around the world.